Table Of Contents

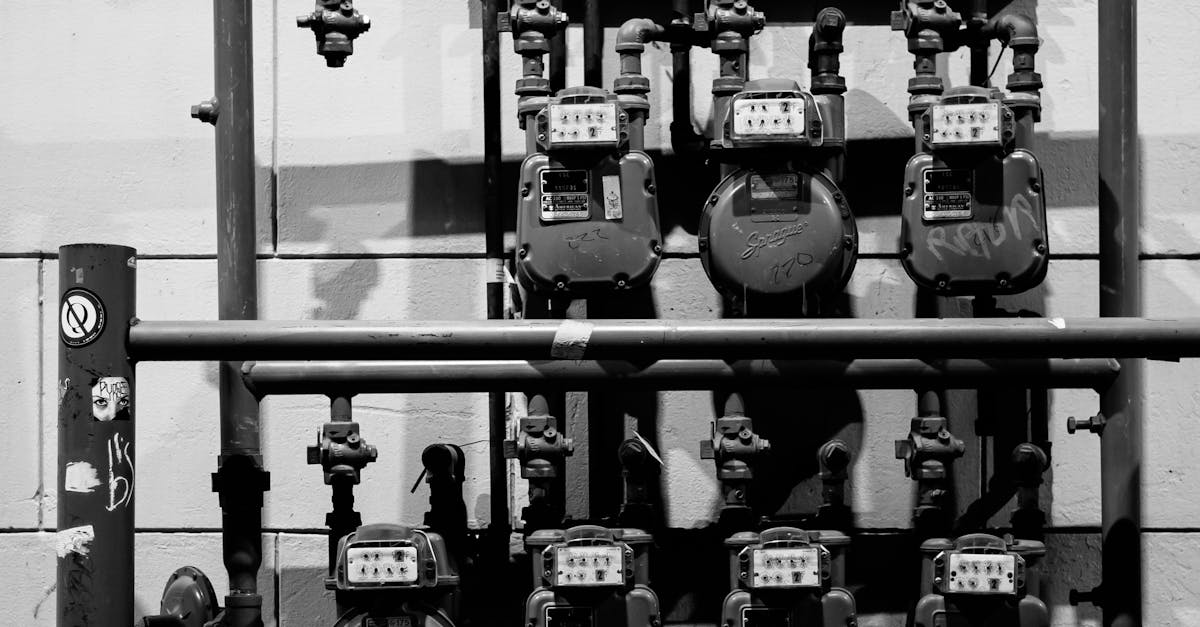

Preparing the Installation Site

Preparing the installation site is a crucial first step in ensuring a safe and efficient gas line installation and repair process. Begin by assessing the area where the gas line will be laid or connected. Clear any debris, vegetation, or obstacles that might hinder the installation. It is important to look for existing underground utilities, such as electricity or water lines, which can pose dangers if disturbed during the project. Proper marking of these utilities can prevent accidents and ensure compliance with local regulations.

Once the area is clear, it's time to evaluate the layout for the gas line installation. Measure the distance from the main supply and plan for the most efficient route. This involves considering bends, elevation changes, and potential hazards that could affect the installation. Proper planning reduces the risk of leaks and improves the overall integrity of the gas line system. Take detailed notes and create diagrams if necessary to keep track of your installation plan.

Clearing and Marking the Area

Before beginning any gas line installation and repair, it is essential to clear and mark the area where the work will be conducted. This involves removing any obstructions such as fences, furniture, or other equipment that may hinder access to the installation site. Ensuring a clear workspace promotes safety and efficiency, allowing for a better focus on the task at hand. Additionally, it is important to check for existing underground utilities, as these can pose a significant risk during the installation process.

After clearing the area, proceed to mark the intended path of the gas line. This can be achieved using paint or flags to delineate the route clearly. The markings should indicate the depth and width of the trench as well as any turns or junctions. Taking the time to accurately mark the area helps prevent accidental damage to other buried services, ensuring a safe installation environment. Careful preparation at this stage lays the groundwork for a successful gas line installation and repair, minimising potential issues later on.

Drafting a Detailed Installation Plan

When embarking on gas line installation and repair, a comprehensive installation plan is essential. Begin by assessing the specific requirements of your project. Identify the type and size of the gas line needed for your particular application. Consider factors such as the distance from the main supply, the intended usage of gas appliances, and any local regulations or codes that might impact your installation. Documenting these details will provide clarity throughout the installation process and help avoid potential setbacks.

Next, create a detailed timeline for your project. Outline each phase of the installation, from initial site preparation to final testing of the gas line. Assign responsibilities if working with a team and ensure everyone understands their roles. Incorporating a checklist of materials and tools required will streamline the process and minimise disruptions. By having a clear plan, you can efficiently navigate through the complexities of gas line installation and repair, ultimately ensuring a safe and successful outcome.

StepbyStep Guide for Your Project

Before commencing with gas line installation and repair, ensure you gather all necessary materials and tools. Familiarise yourself with the local regulations and safety codes relevant to gas line work. Safety is paramount, so wearing appropriate protective gear is essential. Lay out your tools close to the installation site for easy access. Create a checklist of tasks to streamline the process, minimising the chances of oversight.

Once you are prepared, begin by measuring and marking the route for the gas line. It's important to follow your drafted installation plan meticulously. Use a trenching tool to create a trench if you're installing an underground line. Make sure the trench is deep enough to prevent potential damage. After positioning the line, check that all fittings and joints are secure. This detailed approach helps ensure that gas line installation and repair is executed safely and effectively.

Connecting the Gas Line to the Main Supply

Connecting the gas line to the main supply involves careful handling to ensure safety and efficiency. Begin by using appropriate materials that comply with local regulations. It's essential to employ high-quality connections and fittings specifically designed for gas applications. This not only enhances the durability of the installation but also prevents potential leaks. Before proceeding, ensure that all valves are closed and the main supply is safely turned off.

Once the gas line is positioned, secure it firmly to the supply point, making it tight enough to prevent any leaks. It can be beneficial to use thread sealant approved for gas line installation and repair to provide an additional layer of safety. After completing the connection, conduct a thorough leak test using soapy water or a specialised gas leak detector. This step is crucial to identify any escaping gas before the system is put into operation. Always ensure that all safety measures are followed to protect both the installation team and the household.

Techniques for Secure Connections

Ensuring secure connections during gas line installation and repair is crucial for both safety and functionality. When joining sections of the gas line, ensure that they fit snugly without gaps. Using professional-grade fittings and threads is essential; this helps to create a strong seal that can withstand the pressure of gas flow. Additionally, applying a suitable thread sealant designed for gas lines can enhance the integrity of these connections. Regular inspections for wear and tear are advisable, especially in older installations.

Using the appropriate tools is vital for the integrity of the connections. A pipe wrench can provide the necessary leverage when tightening fittings, but care is needed to avoid over-tightening, which could lead to threads being stripped or damage to the fittings. Employing a torque wrench, where applicable, ensures that connections are made to manufacturer specifications. This attention to detail during the gas line installation and repair process helps to mitigate risks associated with gas leaks and enhances the overall performance of the system.

FAQS

What permits do I need to install a gas line?

Before installing a gas line, you typically need to obtain permits from your local council or relevant authority. It's essential to check local regulations to ensure compliance.

Can I install a gas line myself, or should I hire a professional?

While some homeowners may attempt a DIY installation, it is highly recommended to hire a licensed professional to ensure safety and compliance with local codes.

What materials are required for gas line installation?

Common materials include gas pipes (such as copper or polyethylene), fittings, valves, and a gas meter. Always ensure that the materials meet the standards set by your local regulations.

How do I know if the gas line is properly connected?

After installation, you can check for leaks using a soapy water solution. Bubbles will form at any leak points. It’s also advisable to have a professional inspect the installation.

What safety precautions should I take during the installation?

Ensure you have proper ventilation, use protective gear, and turn off the gas supply before beginning the installation. Always follow safety guidelines and regulations to minimise risks.