Table Of Contents

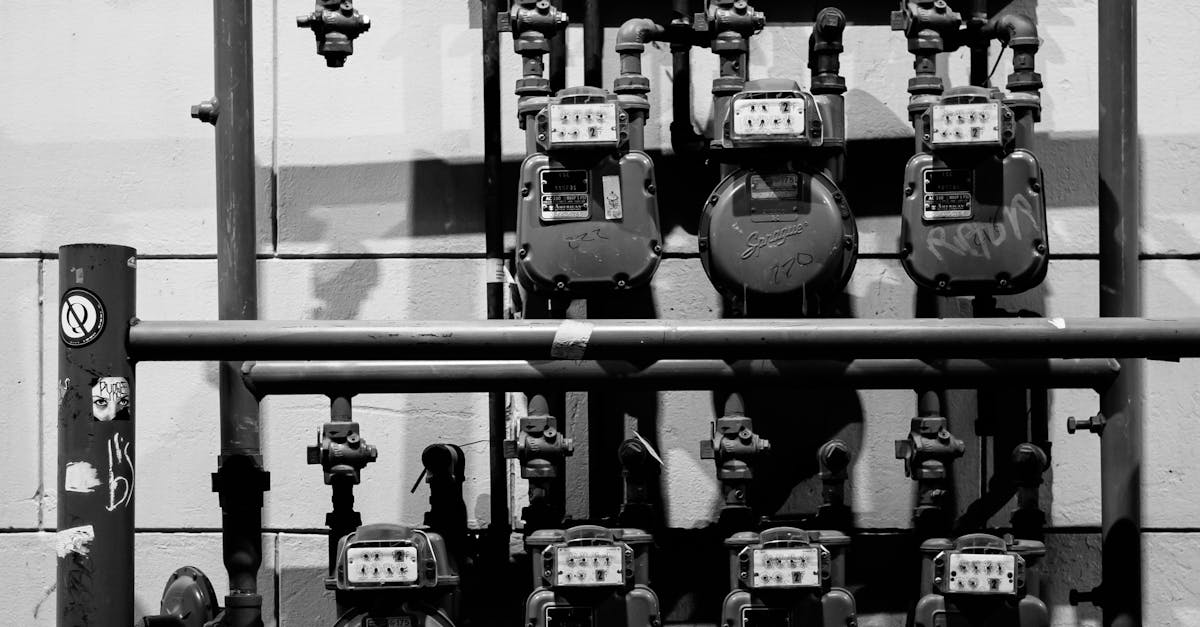

Environmental Impact on Gas Line Lifespan

Gas lines are subject to various environmental factors that can significantly affect their lifespan. Elements such as moisture, soil chemistry, and temperature fluctuations contribute to the deterioration of the materials used in gas lines. Corrosive soils can expedite degradation, while extreme weather conditions like heavy rain or drought can lead to ground movement. This movement places additional stress on gas lines, potentially leading to leaks or failures. Regular inspections are vital in areas prone to such environmental challenges to mitigate risks.

Gas line installation and repair practices also play a crucial role in determining longevity. Ensuring that pipelines are sealed properly and positioned at suitable depths can reduce their exposure to harmful environmental effects. The choice of materials during installation directly influences resilience against both corrosion and physical stress. When maintenance practices are followed rigorously, the integrity of the gas lines can be preserved, extending their useful life even in challenging environmental conditions.

Effects of Weather and Soil Conditions

Weather conditions play a significant role in determining the lifespan of gas lines. Extreme temperatures, both hot and cold, can lead to expansion and contraction of the materials used in gas lines. Moisture from heavy rainfall or melting snow can lead to corrosion, especially in older pipelines that may not be adequately protected. Additionally, persistent exposure to harsh weather can weaken the structural integrity of gas lines, making them more susceptible to leaks and ruptures.

Soil conditions also impact the durability of gas infrastructure. For instance, soil that is highly acidic or contains corrosive materials can accelerate deterioration. The presence of rocks or other hard materials can cause physical damage during installation or subsequent ground movement. To mitigate these risks, gas line installation and repair must take into account local soil types and conditions. Thorough assessments and appropriate protective measures are essential for ensuring the longevity and safety of gas lines in variable environments.

Safety Considerations

Safety considerations are paramount when it comes to gas line installation and repair. Proper installation is crucial to prevent leaks, which can lead to hazardous situations including explosions and environmental contamination. Professionals should adhere to stringent safety protocols and ensure that all components meet industry standards. Regular maintenance checks can identify potential issues early, allowing for timely repairs that mitigate risks associated with gas line failures.

Furthermore, awareness of potential hazards is important for anyone working with or around gas lines. Training for technicians and handlers should encompass the correct procedures for installation, maintenance, and emergency responses. Utilising appropriate materials and tools during gas line installation and repair contributes to a safer environment. Continuous education on the latest safety regulations will help maintain compliance and protect both workers and the public.

Importance of Proper Installation and Usage

Proper installation and usage of gas lines are fundamental to ensuring their longevity and safety. When gas line installation and repair are conducted by qualified professionals, potential issues such as leaks or corrosion can be greatly minimised. Choosing the right materials and adhering to industry guidelines play a critical role in the sustained performance of gas lines. Regular maintenance checks further enhance the safety and efficiency of the system.

Moreover, user awareness is equally important. Homeowners must understand the significance of reporting any unusual smells or sounds associated with gas lines. Prompt action can prevent hazardous situations, making it essential for users to recognise the need for ongoing vigilance. By combining proper installation practices with informed usage, the integrity of gas lines can be preserved, ultimately extending their lifespan.

Regulations and Standards

Regulations and standards play a crucial role in ensuring the safety and longevity of gas lines. In Australia, various codes and guidelines are established to govern the installation, maintenance, and repair of gas infrastructure. Compliance with these regulations helps prevent leaks and other hazards, protecting both the environment and public safety. The Australian Gas Codes outline specific requirements that must be followed by professionals in the industry, promoting consistency and reliability in gas line installation and repair practices.

Adherence to these standards is essential not only for safety but also for ensuring efficient operations. Regular audits and inspections help enforce compliance, making it necessary for gas service providers to stay updated on any changes to regulations. Training for technicians and workers involved in gas line installation and repair is also mandated, ensuring they are knowledgeable about current procedures and safety protocols. This focus on regulatory compliance ultimately enhances the integrity of gas infrastructure within the community.

Compliance with Australian Gas Codes

In Australia, compliance with the relevant gas codes is crucial for ensuring safety and efficiency in gas line installation and repair. These codes outline the necessary standards and practices that must be followed to minimise risks associated with gas leaks and explosions. Adhering to these regulations helps to create a safer environment for both residences and businesses.

Australian gas codes also provide guidelines for the materials and technologies used in gas line installation and repair. These standards ensure that the infrastructure is reliable and can withstand local environmental conditions. Regular inspections and maintenance in line with these codes are essential to prolong the life expectancy of gas lines, ultimately protecting public safety and promoting responsible energy use.

FAQS

What is the typical lifespan of a gas line?

The typical lifespan of a gas line can vary, but it generally ranges from 30 to 50 years, depending on factors like material, installation quality, and environmental conditions.

How do environmental factors impact the lifespan of gas lines?

Environmental factors such as soil composition, moisture levels, and weather conditions can significantly affect the lifespan of gas lines. For example, corrosive soils can shorten the lifespan of metal pipes.

What safety considerations should I keep in mind regarding gas lines?

Key safety considerations include ensuring proper installation, regular maintenance, and immediate reporting of any leaks or damages. Adhering to safety standards and regulations is also crucial.

What are the essential regulations for gas line installation in Australia?

In Australia, gas line installation must comply with the Australian Gas Codes which set standards for safety and performance, ensuring that gas systems are installed and maintained correctly.

How can I extend the life of my gas line?

To extend the life of your gas line, ensure regular inspections, schedule maintenance, use high-quality materials for installation, and address any issues promptly to prevent further damage.