Table Of Contents

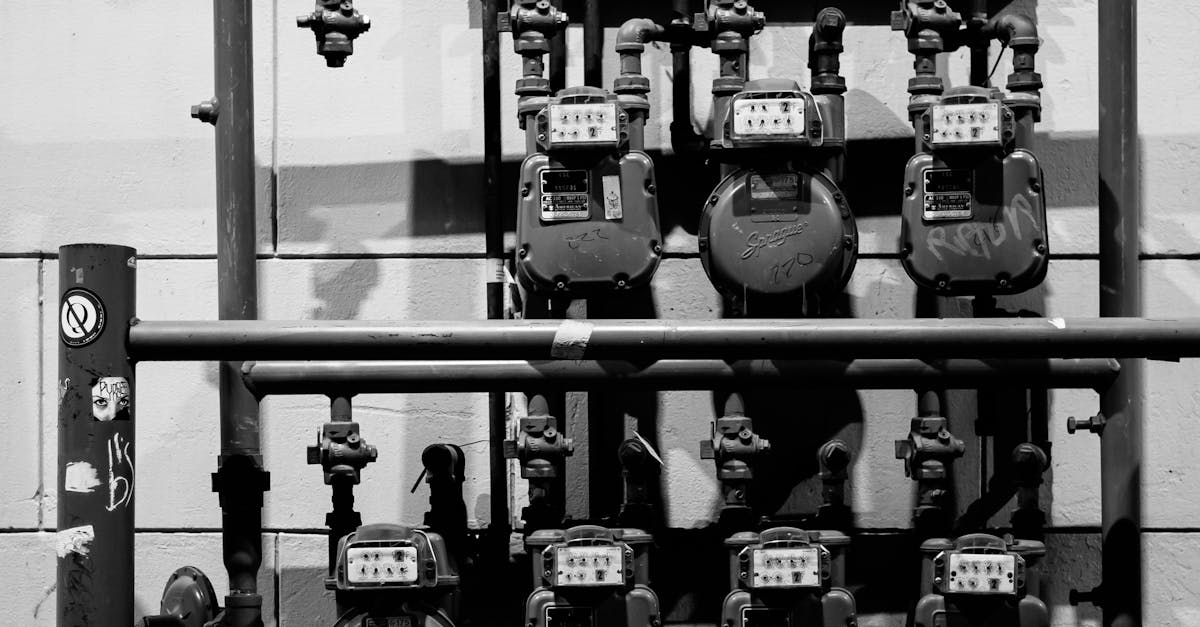

Techniques for Excavating Gas Line Trenches

Excavating trenches for gas lines requires careful planning and execution to ensure safety and compliance with regulations. Typically, the trench should be of adequate depth and width to accommodate the gas line while providing sufficient space for any necessary fittings. Mechanical tools such as excavators and trenchers are often employed for larger projects, allowing for efficient digging. Hand tools may be used in tighter areas where machinery cannot access, ensuring that the dimensions align with local safety codes.

In addition to depth and width considerations, soil conditions play a significant role in the excavation process. Operators must assess the soil type, which can influence equipment choice and digging techniques. Understanding the specific requirements for gas line installation and repair can guide the selection of appropriate methods. Precise excavation is essential to avoid damaging existing utilities and to maintain the structural integrity of the surrounding environment.

Tools and Methods for Safe Digging

When it comes to safe digging for gas line installation and repair, employing the right tools is paramount. A digger or excavator can efficiently shift soil, especially in larger projects, while hand tools like shovels and spades are essential for more precise work. It is crucial to keep a safe distance from the gas line's designated depth, ensuring that the soil is carefully excavated to avoid any accidental damage. Ground-penetrating radar can also be a valuable resource to safely locate existing gas lines before any digging begins, reducing the risk of hitting live utilities.

In addition to proper tools, adhering to specific methods helps enhance safety during excavation. Marking the dig area and notifying utility companies before commencing any work ensures that hazards are minimised. Flagging the site also alerts others to the potential dangers present. Utilising air excavation techniques can further safeguard against damaging gas lines. This method involves using compressed air to displace soil, providing a clear view of the gas line while keeping it intact.

Signs of Buried Gas Line Issues

Identifying signs of buried gas line issues is crucial for safety and efficiency. Homeowners should remain vigilant for any unusual scents resembling rotten eggs, a definite indication of a potential gas leak. Bubbles in wet areas of the yard or patches of dead vegetation can also signal underlying problems. If there are frequent increases in gas bills without a corresponding increase in usage, it may be prudent to investigate further.

Gas line installation and repair must be performed with precision to prevent future complications. Regular checks for stale or strange odours near gas appliances are vital. Moreover, any unusual hissing sounds near the ground may indicate a leak. Addressing these symptoms promptly can help avoid unsafe conditions and ensure the longevity of the gas line infrastructure.

Indicators of Potential Problems

Identifying potential problems with buried gas lines is crucial for maintaining safety in both residential and commercial settings. One of the most common indicators is the presence of unusual odours, often described as a sulphur-like smell or rotten eggs, which signals a possible gas leak. Homeowners should remain vigilant for other signs such as the formation of dead patches in grass or plants, as this may indicate that gas is escaping into the soil and affecting plant health. Regular inspections and prompt attention to these symptoms can greatly mitigate risks associated with gas line installation and repair.

Visual cues also play an important role in detecting potential issues. Look for any bubbling or hissing sounds emerging from the ground, which may suggest a leak. Additionally, ground movement or noticeable displacement in soil can signify shifting pipes or an area where gas pressure is compromised. It is vital to keep an eye out for such abnormalities, as they can lead to dangerous situations if left unaddressed. Conducting routine checks can ensure that any problems are discovered early in the gas line installation and repair process.

Maintenance Practices for Underground Gas Lines

Regular inspection of underground gas lines is crucial for identifying potential issues before they escalate. Implementing a schedule for routine checks allows for the early detection of leaks or corrosion. During these inspections, important factors such as the integrity of valves, joints, and connections should be assessed. Proper documentation of findings contributes to a comprehensive maintenance record, which aids in future repair and planning activities.

Gas line installation and repair require adherence to strict industry standards to ensure safety and operational efficiency. It is essential to work with certified professionals who are knowledgeable about local regulations. In addition to the installation checks, routine maintenance should also include monitoring surrounding vegetation and soil conditions, as these can affect the stability of the lines. Training staff on emergency procedures can enhance safety in case of an incident, ensuring that everyone knows how to respond appropriately.

Ensuring LongTerm Safety and Efficiency

Regular maintenance of underground gas lines is crucial for ensuring long-term safety and efficiency. Scheduled inspections can identify potential issues before they escalate into serious problems. Having qualified professionals conduct these checks helps assess the integrity of the gas lines and their surrounding infrastructure. Any signs of wear or damage should be addressed promptly to avoid safety hazards.

Gas line installation and repair should always adhere to local regulations and guidelines. Up-to-date practices and technological advancements enhance the reliability of the gas distribution system. Properly trained personnel should carry out all installation and repair work to minimise risks. Implementing robust safety protocols during these processes further supports the longevity and dependability of gas lines.

FAQS

How deep should a gas line be buried in Australia?

In Australia, gas lines are typically required to be buried at a minimum depth of 600 mm, although this can vary based on local regulations and environmental factors.

What factors influence the required depth for burying a gas line?

Several factors can influence the required depth, including soil type, the potential for ground movement, the presence of other underground utilities, and local building codes.

Are there specific tools recommended for digging around gas lines?

Yes, tools such as a post-hole digger, hand trowels, and vacuum excavation equipment are recommended for safely digging around gas lines to minimise the risk of damage.

How can I identify if a buried gas line is experiencing issues?

Signs of potential gas line issues include unusual gas odours, dead vegetation above the line, or bubbles in wet areas near where the line is buried.

What maintenance practices should be followed for underground gas lines?

Regular inspections, monitoring for signs of leaks or damage, and ensuring that the area around the gas line is free from heavy machinery or excessive digging are important maintenance practices.