Table Of Contents

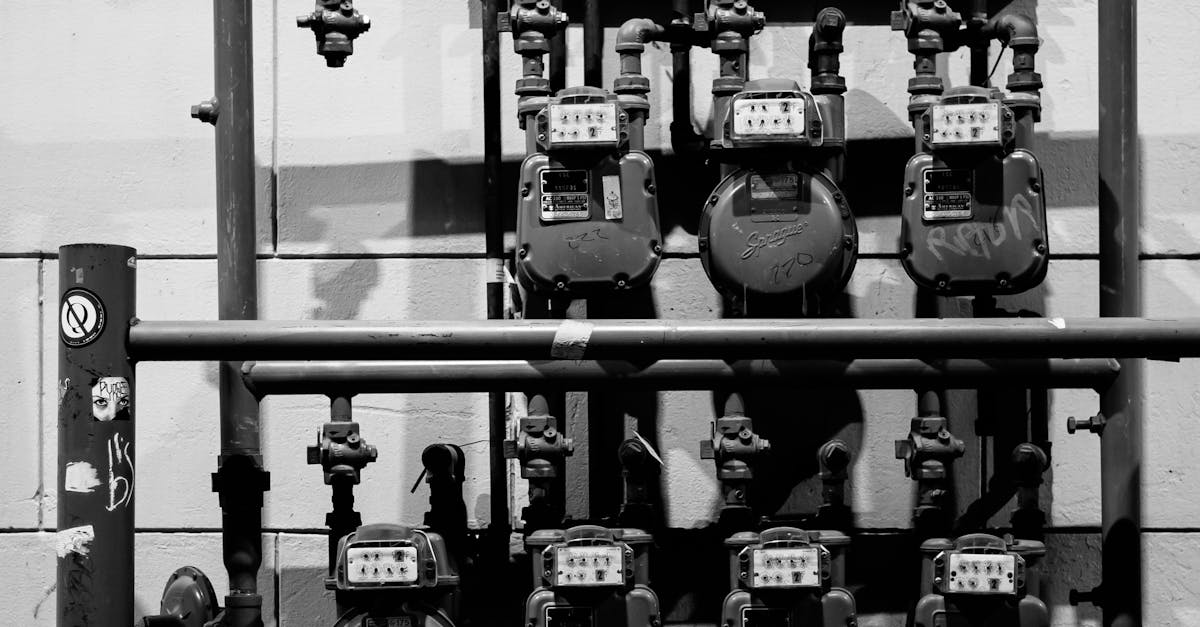

Tools and Equipment Used

Repairing a gas line leak requires specific tools and equipment to ensure safety and effectiveness. A gas leak detector is essential for identifying the precise location of the leak. Proper personal protective equipment, such as gloves and safety goggles, protects the worker during repairs. Additionally, a pipe wrench is crucial for tightening or loosening fittings, while Teflon tape aids in sealing joints effectively. Gas line installation and repair often necessitate the use of specialised tools like a pipe cutter and a socket set, ensuring a precise fit and secure connections.

Depending on the complexity of the leak, a range of other equipment may also be needed. For example, if a section of the gas line requires replacement, a tubing bender may be used to create the necessary angles. Some repairs might also necessitate a pressure gauge to check the integrity of the gas line after repairs are completed. Having the right tools is vital not only for efficiency but also for maintaining safety standards when working with gas lines.

Essential Gear for Effective Repairs

When tackling gas line installation and repair, having the right tools is paramount for ensuring safety and efficiency. Basic essential gear includes a pipe wrench, adjustable spanner, and Teflon tape. These items facilitate secure connections and prevent leaks, which are critical during installation. Additionally, a gas detector is vital for identifying any leaks in the system before and after repairs are made. Safety goggles and gloves should also be on hand to protect against any hazardous materials during the process.

In more complex situations, specialised equipment may be required for effective repairs. A gas pressure gauge helps monitor and maintain the correct pressure levels in the system, ensuring optimal performance. Furthermore, a soldering torch may be necessary for certain types of connections, particularly when dealing with metal pipes. Having access to these additional tools not only streamlines the repair process but also increases the overall safety of gas line installation and repair, reducing the risk of faulty work and ensuring compliance with regulatory standards.

DIY vs Professional Help

Taking on gas line installation and repair as a do-it-yourself project can appeal to homeowners looking to save on costs. Basic knowledge of plumbing and gas systems may allow for minor fixes. Resources such as online tutorials and DIY guides can provide helpful insights. However, improper handling of gas lines can lead to serious safety hazards, including leaks or explosions.

Choosing to hire a professional for gas line installation and repair typically ensures adherence to safety standards and local regulations. Certified technicians have the experience and appropriate tools to diagnose issues accurately. While this option may come with a higher upfront cost, the peace of mind that comes from knowing the job is done correctly can outweigh the initial expense. Professional assistance can also prevent potential future complications, which might save money in the long run.

Weighing the Pros and Cons

When considering whether to tackle gas line installation and repair yourself or to hire a professional, it is crucial to assess your own skills and the complexity of the task. DIY projects may seem appealing due to the potential cost savings and the satisfaction of completing a job independently. However, the risks associated with handling gas lines can be significant. A lack of experience increases the chances of improper installation or repair, which could lead to dangerous leaks or further damage.

On the other hand, employing a professional ensures that the work meets safety standards and regulations. Experts have the necessary training and tools to handle gas line installation and repair effectively. While this option may incur higher upfront costs, it is an investment in safety and peace of mind. Choosing the right route requires careful consideration of the potential risks and the advantages of professional expertise.

Cost Implications of Repairs

When considering the cost implications of repairs, it is vital to evaluate various factors that influence pricing. Gas line installation and repair costs can vary significantly based on the complexity of the leak, the materials needed, and the local labour rates. A minor repair may only require basic tools and a few hours of labour, whereas major leaks could necessitate extensive work, specialised equipment, and potentially even permits, which will drive up the expenses.

It is also important to consider long-term savings when investing in high-quality repairs. While initial costs might appear steep, opting for professional services ensures adherence to safety regulations, which can prevent future issues and additional expenses. Furthermore, improperly handled repairs can lead to hazards and costly damages, reinforcing the need to factor in not only immediate costs but also the potential risks of inadequate work.

Understanding Pricing Factors

When considering the costs associated with gas line leaks, several factors come into play. The materials required for repairs, such as piping, fittings, and sealants, significantly influence the overall expenses. Availability of these materials in local stores can also affect pricing. In addition, the complexity of the repair job can either elevate or reduce costs. If the leak is located in a difficult-to-access area, the labour required will likely increase, leading to higher service charges from professionals.

Moreover, whether a DIY approach or professional help is chosen has substantial implications on the total cost. While tackling repairs independently may save on labour expenses, it is crucial to factor in the potential costs of tools and equipment necessary for effective repairs. Gas line installation and repair often require specialised tools that may not be readily available to the average homeowner. Professionals not only have the expertise to identify and fix leaks efficiently but also carry the appropriate insurance, which can mitigate financial risks associated with accidents during repair work.

FAQS

How long does it typically take to repair a gas line leak?

The time required to repair a gas line leak can vary widely, but most repairs can be completed within a few hours to a day, depending on the severity of the leak and the location of the damage.

What are the signs of a gas line leak?

Common signs of a gas line leak include a distinct smell of gas (often likened to rotten eggs), hissing sounds near gas lines, dead or dying vegetation in the surrounding area, and higher-than-normal gas bills.

Can I repair a gas line leak myself?

While some minor gas line issues can be managed with DIY methods, it is highly recommended to seek professional help for repairs to ensure safety and compliance with local regulations.

What tools and equipment are necessary for repairing a gas line leak?

Essential tools for repairing a gas line leak typically include wrenches, pipe cutters, Teflon tape, gas line fittings, and safety gear such as gloves and goggles.

What factors can affect the cost of repairing a gas line leak?

The cost of repairs can be influenced by factors such as the location of the leak, the type of materials needed, labour costs, and the complexity of the repair work required.