Table Of Contents

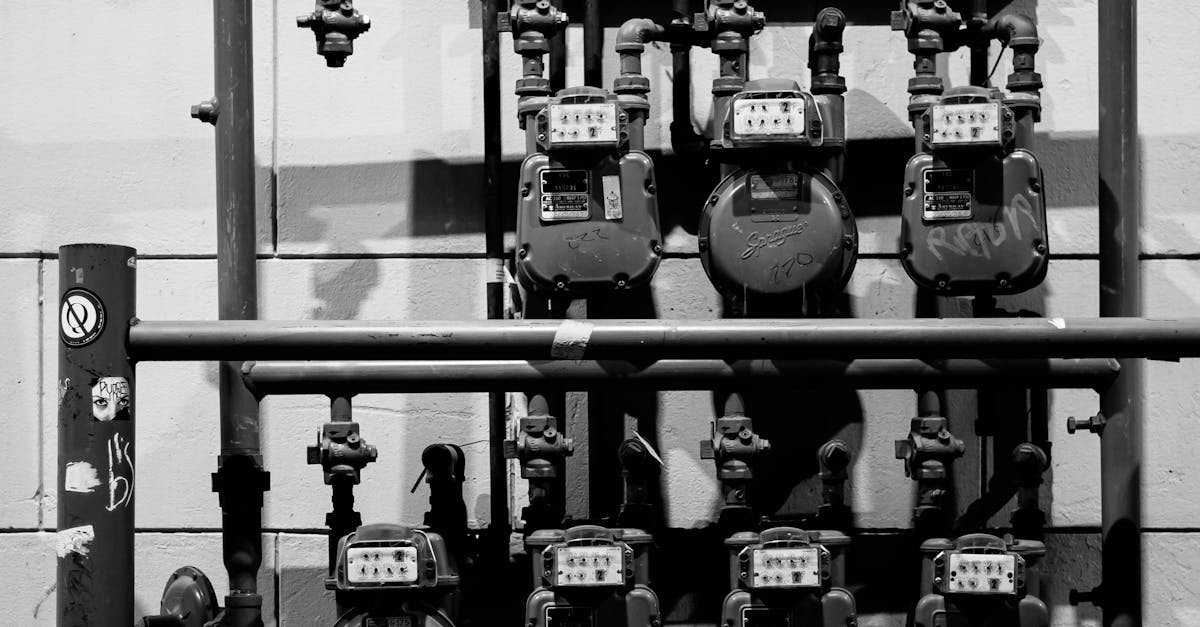

Testing for Leaks

Ensuring safety during and after connecting an Australian gas bayonet fitting involves thorough leak testing. After the connection is completed, it is vital to check for any potential leaks in the gas line. One effective method is to apply a soap solution to the joints and connections. If bubbles form, it's a clear indication that gas is escaping. This simple and affordable test can help homeowners maintain their safety by identifying issues before they escalate.

Gas line installation and repair can sometimes lead to inadvertent problems, making detection of leaks crucial for ongoing safety. In addition to the soap test, using a gas leak detector is another practical approach. These electronic devices can precisely pick up gas presence even before human detection, providing an added layer of security. Regular checks, regardless of the method, should be incorporated into routine maintenance to ensure the integrity of the system remains intact.

Methods to Check for Gas Leaks

Detecting gas leaks is crucial for safety when dealing with an Australian gas bayonet fitting. One simple method is to mix equal parts of water and dishwashing liquid. Apply this mixture directly onto the connections and fittings. If bubbles form, you have identified a leak. This method can easily be done at home and requires no specialised tools.

Professional gas line installation and repair might involve more advanced techniques, such as using a gas leak detector. These portable devices can accurately identify the presence of gas even in small amounts. Similarly, a soapy water solution is an effective first step, but investing in a leak detector provides an extra layer of reassurance for ongoing safety. Regular maintenance checks help mitigate risks associated with gas leaks, ensuring peace of mind for users.

Regulating the Gas Supply

Regulating the gas supply is essential for ensuring that appliances operate efficiently and safely. When connecting to an Australian gas bayonet fitting, it’s important to adjust the flow to meet the requirements of the specific appliance being used. Each device may have its own specifications regarding gas pressure and volume, which are crucial for optimal performance. Regular checks of the connections and the regulator can help maintain consistent gas flow and prevent any potential hazards.

For those unfamiliar with gas line installation and repair, understanding the components involved in gas regulation is key. A gas regulator controls the pressure of gas delivered to an appliance. If the pressure is too high or too low, it can lead to various issues, such as inefficient appliance operation or increased risk of leaks. Proper maintenance and adjustments to the regulator ensure appliances receive the correct amount of gas, contributing to effective and safe usage.

Adjusting the Flow for Appliances

Adjusting the flow of gas to appliances is crucial for ensuring safe and efficient operation. If the appliance has a regulator, it typically allows for fine-tuning of the gas pressure, which can aid in achieving optimal performance. It is important to consult the manufacturer’s specifications for the appliances to set the right pressure and flow rate. Always ensure nothing obstructs the appliance's air intake and that it operates within the recommended guidelines.

In some cases, the existing gas line might require modification to accommodate the new appliance’s flow requirements. Gas line installation and repair should only be performed by a licensed professional to guarantee safety. Regular checks of the system can help prevent any issues that may affect gas delivery and performance, ensuring appliances run smoothly and efficiently. Proper adjustment not only enhances functionality but also contributes to energy efficiency, making it a vital aspect of appliance management.

Troubleshooting Common Issues

When dealing with common issues related to gas bayonet fittings, identifying the root cause is essential for ensuring safety and functionality. One of the main concerns is the integrity of the connection. If you've noticed irregularities, such as hissing sounds or the smell of gas, it's vital to conduct a thorough inspection. Check for visible signs of wear or damage on the fittings and hoses. Gas line installation and repair professionals can provide insights and assistance if you face persistent problems.

Another common issue involves flow restrictions due to improper installation or blockages. If appliances are not receiving sufficient gas, it can lead to inefficient operation or failure to ignite. Ensuring that all connections are secure and that there are no obstructions in the line is crucial. Consider consulting with a qualified technician for any adjustments needed. They can ensure that the gas flow is regulated properly without compromising safety or performance.

Identifying and Solving Connection Problems

When connecting an Australian gas bayonet fitting, problems can arise due to various reasons. A common issue is misalignment between the fitting and the appliance. This misalignment may prevent a proper seal, leading to potential leaks. If the connection appears loose or does not fit snugly, it is essential to inspect the fitting thoroughly. Ensure that any threads are clean and free of debris. Sometimes, applying a small amount of thread sealant can help achieve a better fit, but be cautious not to overapply, as it could create additional complications.

Another frequent problem involves insufficient tightening of the fittings. Some users may hesitate to tighten connections thoroughly for fear of damaging the threads, but this can lead to dangerous gas leaks. A properly tightened connection is crucial for safety. If you continue to experience difficulties with the connection, seek professional assistance, especially if you are unsure about handling gas line installation and repair. Trained professionals will have the expertise to address any underlying issues, ensuring a secure and safe connection.

FAQS

What is a gas bayonet fitting?

A gas bayonet fitting is a type of connector that allows for the quick and safe attachment of gas appliances, such as heaters and barbecues, to the gas supply in Australian homes.

How can I test for gas leaks after connecting a bayonet fitting?

You can test for gas leaks by applying a soapy water solution to the connection points. If bubbles form, it indicates a leak. Alternatively, you can use a gas leak detector available at hardware stores.

What should I do if I find a gas leak?

If you detect a gas leak, turn off the gas supply immediately, ventilate the area, and avoid using electrical appliances or creating any flames. Contact a licensed gas fitter to assess and repair the issue.

How do I adjust the gas flow for my appliances?

To adjust the gas flow, locate the adjustable regulator on your gas supply line. You may need to turn a screw or dial to increase or decrease the gas pressure, but it’s recommended to consult the appliance’s manual or a professional for specific instructions.

What common issues might I encounter with a gas bayonet fitting?

Common issues include loose connections, gas leaks, or improper installation. If appliances aren't receiving gas, ensure the bayonet fitting is securely connected and check for any obstructions in the gas supply line. If problems persist, consult a qualified gas fitter.