Table Of Contents

Safety Protocols in Gas Engineering

Safety protocols in gas engineering are critical to ensure the well-being of both technicians and the public. Gas engineers must regularly adhere to strict regulations that govern the installation, servicing, and maintenance of gas appliances. These guidelines are designed to prevent leaks and mitigate the risks of fire or explosions. Training and certification play a pivotal role in apprenticeship programmes, which equip engineers with the skills needed to handle gas safely.

Compliance with safety standards is not just a legal requirement; it is essential for maintaining trust between gas engineers and their clients. When seeking gas fitting repair services, customers rely on the assurance that qualified professionals will perform their work according to established safety protocols. Continuous professional development and the use of modern equipment are vital for engineers to remain updated on the latest safety measures in an ever-evolving industry.

Importance of Compliance with Safety Standards

Compliance with safety standards is vital for ensuring the safety of both the gas engineer and the public. Gas fitting requires a thorough understanding of regulations set by authorities to prevent any potential hazards. Engineers must be familiar with these regulations to avoid serious consequences that may arise from non-compliance. Regular training and up-to-date knowledge on codes governing gas installation and maintenance are essential parts of a gas engineer’s role.

Moreover, offering gas fitting repair services without adherence to safety standards can result in malfunctioning systems that pose risks like explosions or gas leaks. The implications of neglecting these protocols extend beyond immediate safety concerns, potentially leading to significant legal repercussions for both the service provider and property owner. Maintaining rigorous compliance not only protects lives but also ensures the integrity of the systems being installed or repaired.

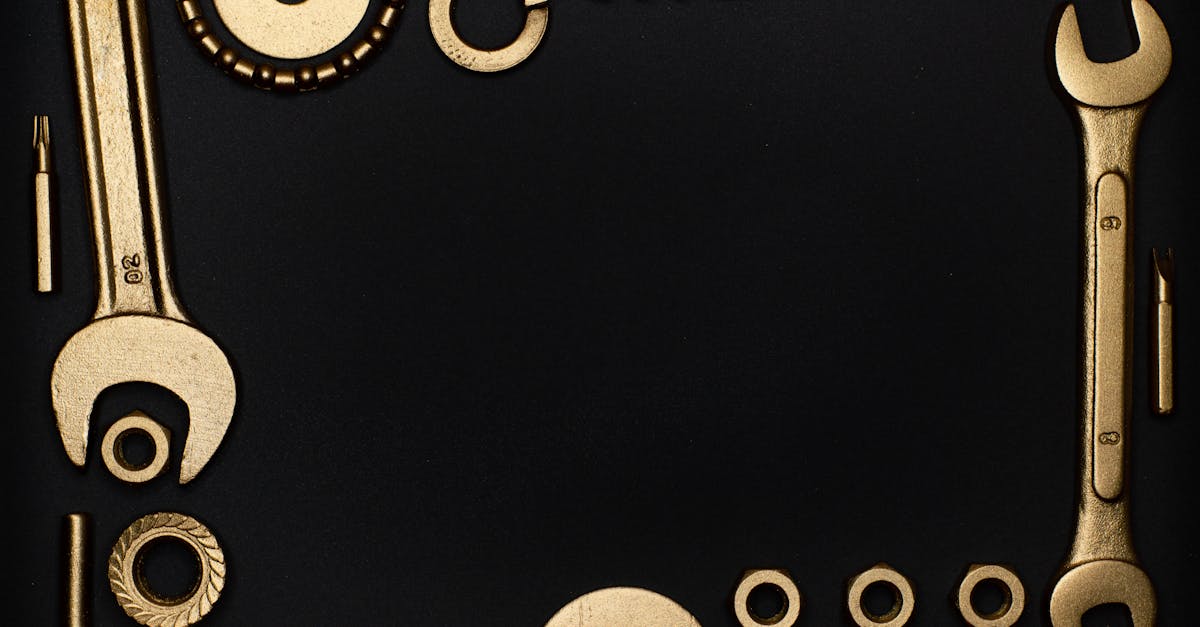

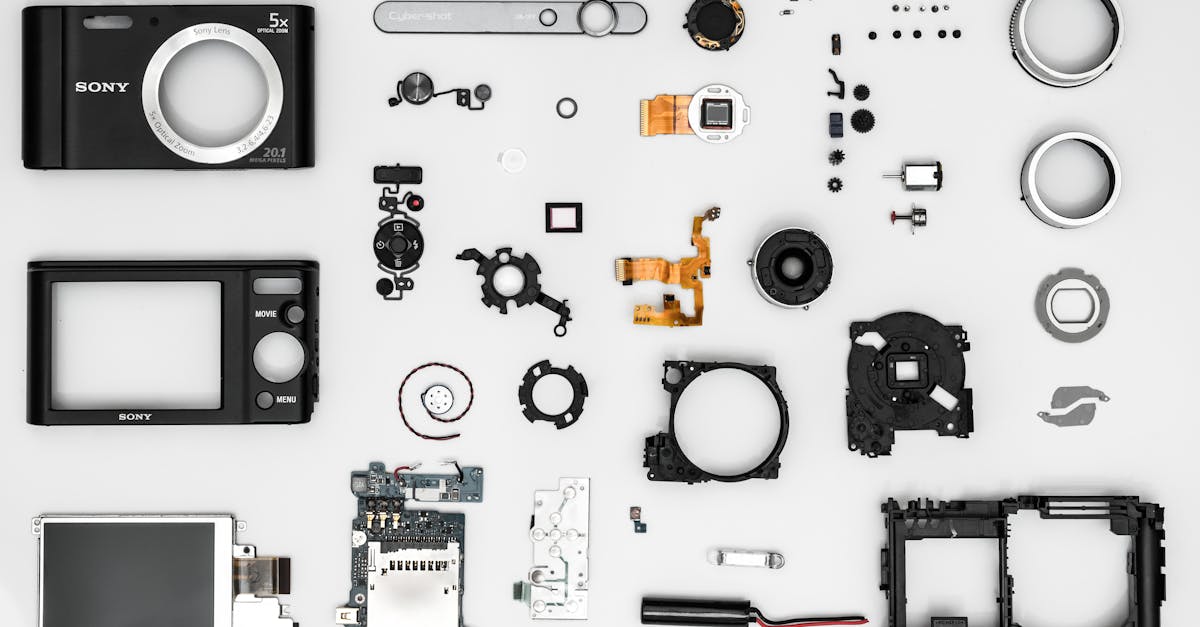

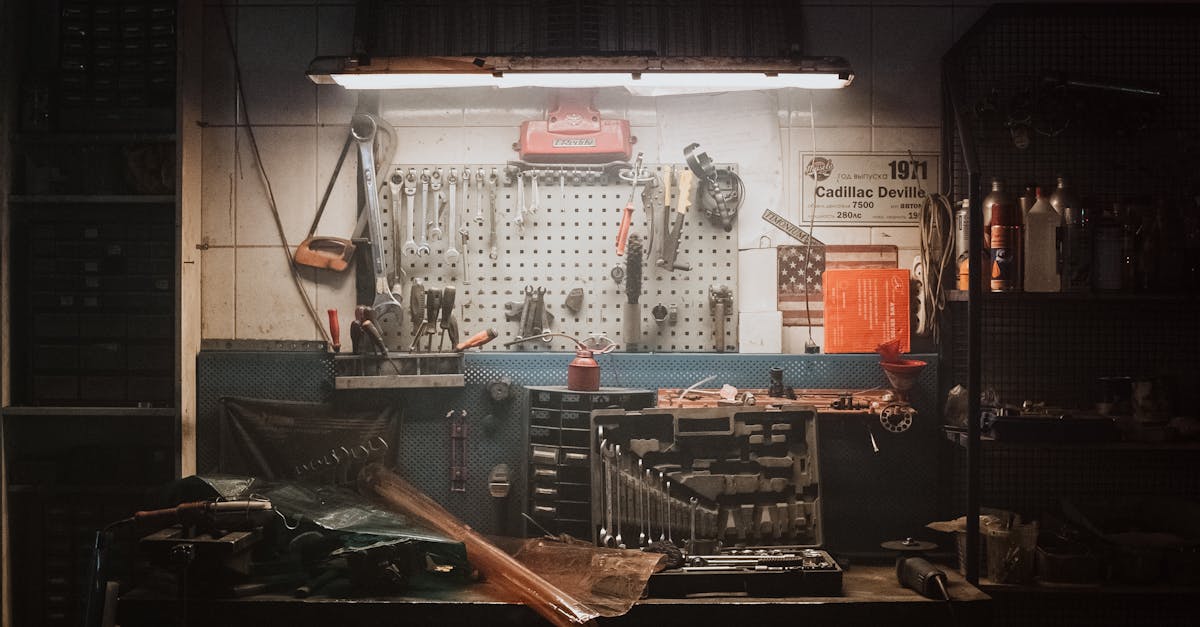

Common Tools Used by Gas Engineers

Gas engineers rely on a variety of specialised tools to ensure safe and efficient installations and repairs. Key equipment includes gas pressure testers, which are essential for diagnosing issues in gas lines. These testers help to identify leaks by measuring the pressure within the system. Additionally, gas engineers utilise multimeters to check electrical components associated with gas appliances, ensuring proper functionality and safety.

Another important tool in a gas engineer's arsenal is the flue gas analyser. This device evaluates the efficiency of combustion in gas appliances, providing insights into operational safety and performance. For those involved in gas fitting repair services, having the correct tools is vital not only for effective troubleshooting but also for maintaining compliance with stringent safety regulations. Tool selection ultimately impacts the reliability of installations and the overall safety of the systems being serviced.

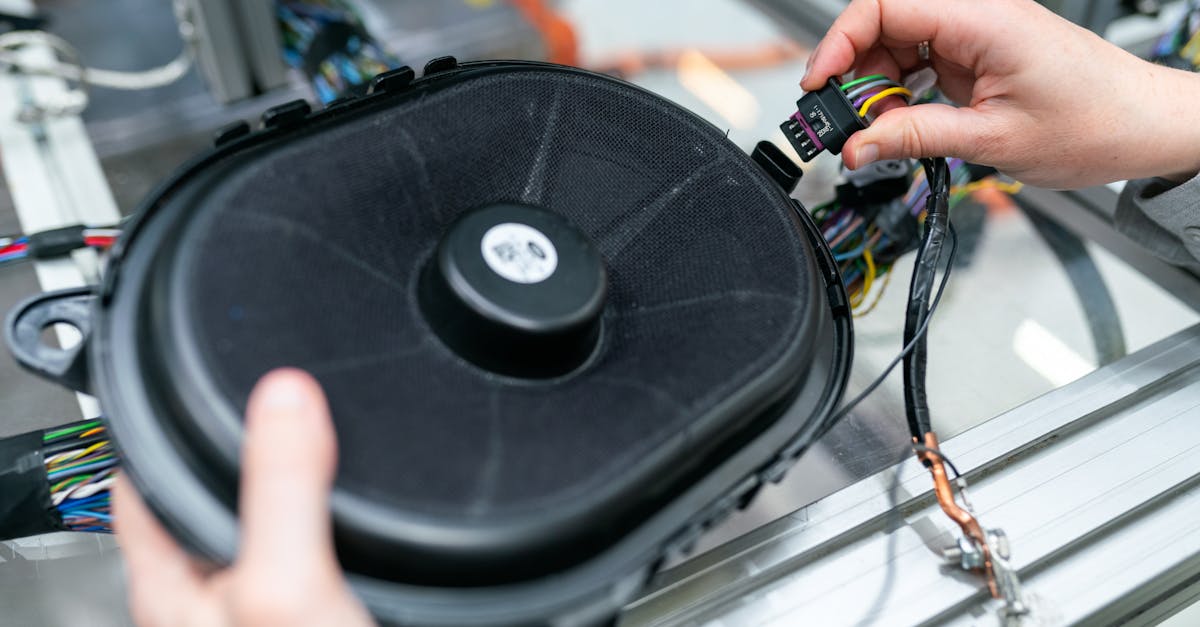

Equipment Specific to Gas Installation and Repair

Gas engineers rely on a specific set of tools tailored for gas installation and repair tasks. Pressure testing equipment is essential for ensuring that gas lines are sealed and functioning correctly. Additionally, gas leak detectors are vital for identifying potential leaks in systems, providing peace of mind for both engineers and customers alike. Tools such as adjustable wrenches and gas pipe cutters are frequently used in installations, allowing for precise modifications and connections in rigid piping systems.

Safety is paramount in the field of gas installation. Engineers often utilise tools like venturi meters to measure gas flow accurately. Alongside this, they may also employ manometers to gauge the pressure within gas lines. Gas fitting repair services require thorough attention to detail, utilising these tools to maintain compliance with industry safety standards, which ultimately protects both the user and the integrity of the gas systems installed.

Typical Tools Utilized by Plumbers

Plumbers rely on a diverse range of tools to effectively carry out their tasks. Commonly used items include wrenches, pipe cutters, and plungers, each serving a specific purpose in plumbing repairs and installations. Wrenches facilitate the tightening and loosening of nuts and bolts, while pipe cutters allow for precise cuts in various materials, ensuring a snug fit. A plunger is essential for clearing clogged drains, showcasing the variety of challenges plumbers encounter daily.

In addition to traditional hand tools, plumbers often incorporate power tools to enhance efficiency and accuracy in their work. Drill machines help create holes for waterlines or fittings, and augers are instrumental in removing blockages. For those who also handle gas fitting repair services, a well-stocked toolkit becomes crucial to ensure both plumbing and gas systems operate safely and seamlessly. The integration of these tools allows plumbers to tackle a wide array of projects, maintaining water and gas flow throughout properties.

Essential Equipment for Plumbing Tasks

Plumbers rely on a variety of tools to tackle everyday tasks efficiently. Essential equipment includes pipe wrenches, which provide the leverage needed to tighten or loosen plumbing fittings. Other critical tools are pliers, pipe cutters, and drain snakes. These instruments enable plumbers to handle various situations, from unclogging drains to installing new piping systems. Each tool plays a role in ensuring the job is completed correctly and safely.

For those specialising in gas fitting repair services, additional equipment is necessary. Gas leak detection kits help identify leaks, ensuring safety during repairs. Pressure gauges allow for the monitoring of gas pressure in systems, confirming they function within safe parameters. Tools specific to gas installations, such as tube benders and gas aiming tools, complement the plumber's toolkit. These instruments highlight the distinct yet overlapping skill sets found in plumbing and gas fitting professions.

FAQS

What qualifications does a gas engineer need?

A gas engineer must complete specific training and obtain relevant certifications, such as a Certificate III in Gas Fitting, and hold a valid gas work licence to ensure they are qualified to handle gas installations and repairs safely.

Can a plumber work on gas appliances?

Not without the proper qualifications. While some plumbers may have additional training in gas work, only licensed gas engineers are authorised to install, service, or repair gas appliances.

What are the main responsibilities of a gas engineer?

A gas engineer's main responsibilities include installing, maintaining, and repairing gas appliances and systems, ensuring compliance with safety regulations, and conducting regular safety inspections.

How do safety protocols differ between gas engineers and plumbers?

Gas engineers follow stringent safety protocols due to the risks associated with gas, including adherence to specific regulations and standards. Plumbers also follow safety protocols, but the focus is primarily on water systems and drainage, which carry different risks.

What types of tools do gas engineers use that plumbers do not?

Gas engineers often use specialised tools such as gas leak detectors, manometers, and flue gas analysers, which are specifically designed for gas installation and maintenance tasks. Plumbers use tools more geared towards plumbing systems, such as pipe wrenches and drain snakes.