Table Of Contents

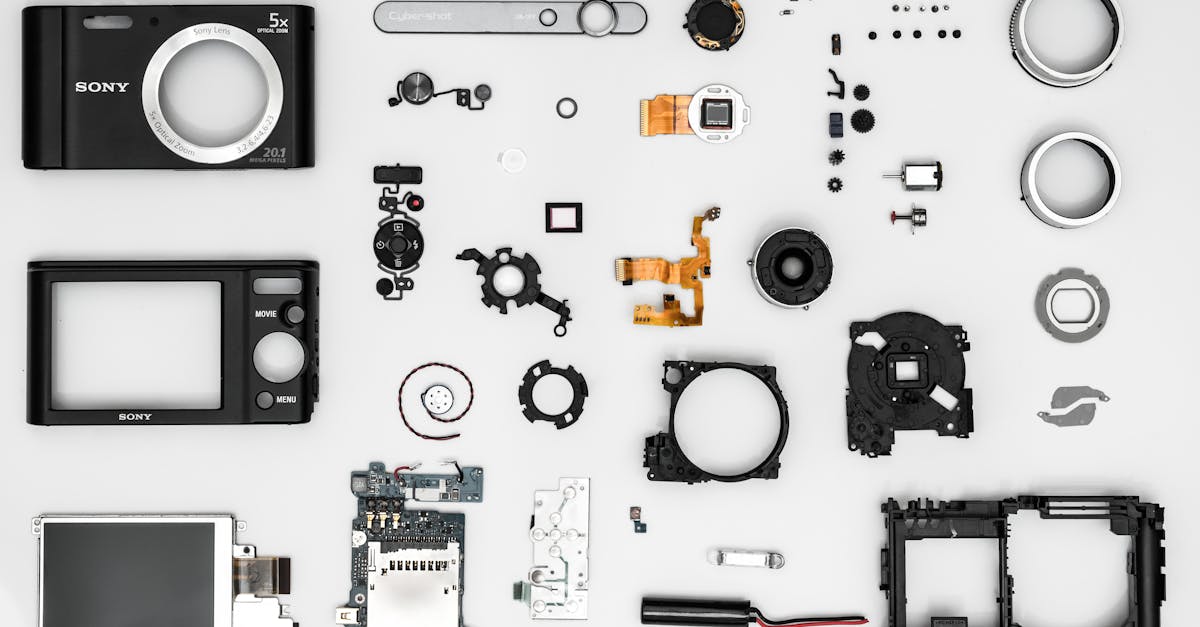

Applying Sealant to the Gas Joint

To effectively seal a leaking gas joint, the application of a suitable sealant is crucial. Begin by thoroughly cleaning the joint to remove any debris, old sealant, or oil that may impede adhesion. Once clean, apply the chosen sealant around the threads of the joint in a continuous motion. Ensure coverage without excessive buildup, as this could lead to further complications during reassembly. It’s essential to select a sealant specifically designed for gas fittings to guarantee compatibility with the gas type being used.

After applying the sealant, carefully reassemble the joint by tightening it to the manufacturer's specifications. A steady and even pressure is vital to maintain a secure fit and to avoid damaging the threads. If you're uncertain about the process or lack the necessary experience, seeking gas fitting repair services can provide professional assistance. This ensures that the seal is not only effective but also safe and compliant with local regulations.

Types of Sealants Suitable for Gas Joints

When selecting sealants for gas joints, it is essential to choose products specifically designed for the purpose. Thread sealants, commonly referred to as pipe dope, are often used in gas fittings due to their ability to create a robust seal. These sealants are typically available in liquid or paste form and are effective for both metal and plastic threads. Always ensure the product is rated for gas applications to avoid any safety issues.

Liquid gasket adhesives are another option suitable for gas joints. These adhesives can fill gaps effectively and are resistant to the pressures typically found in gas fittings. It's crucial to apply these sealants correctly to prevent leaks. If there's ever any uncertainty, consulting professional gas fitting repair services can provide guidance on the appropriate products and methods to use. Prioritising safety and compliance with local regulations ensures the integrity of your gas installations.

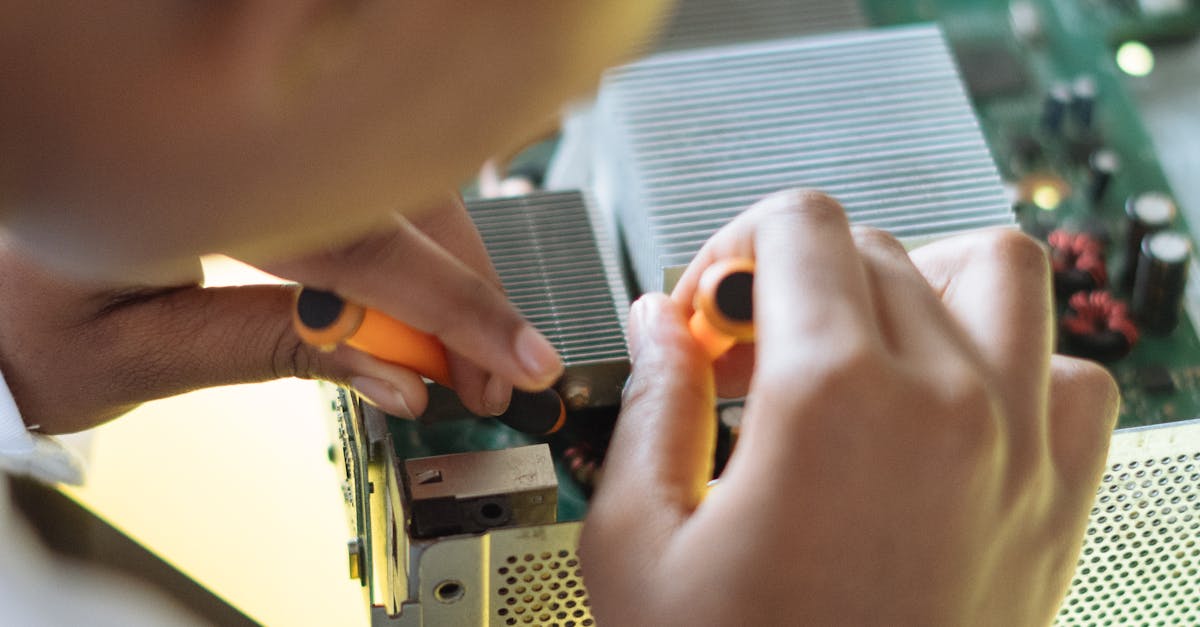

Reassembling the Joint

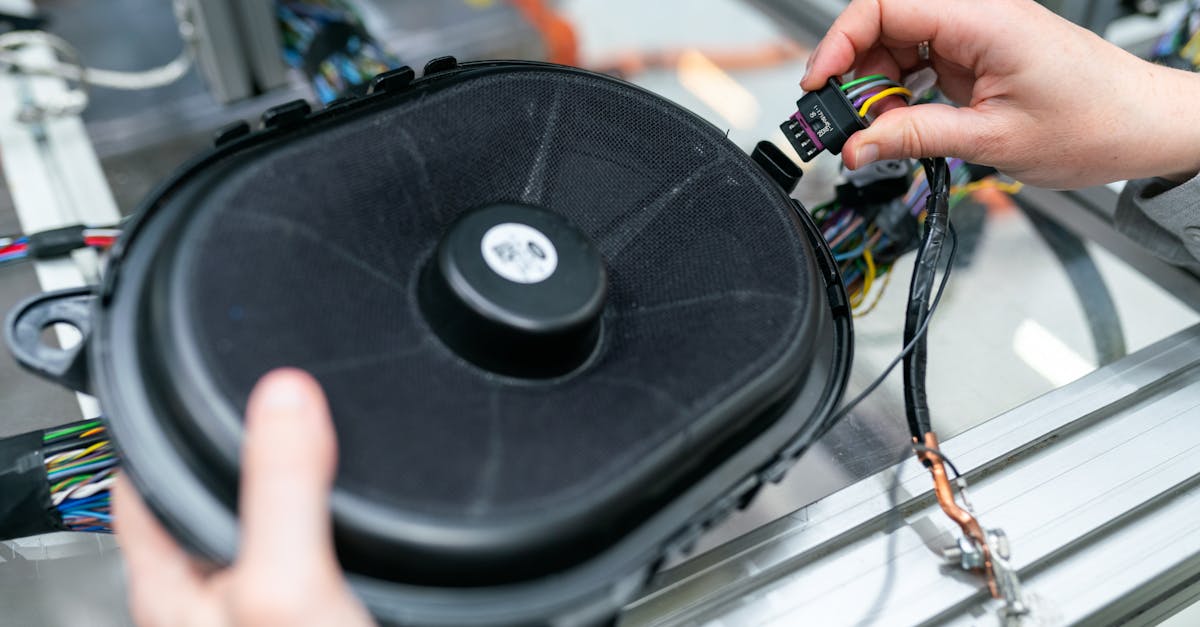

Reassembling a leaking gas joint requires careful attention to detail. Begin by ensuring that all surfaces are clean and free of debris. This prepares the joints for a secure fit. Position the components correctly, making sure that any sealing materials are aligned properly. Tightening should be done gradually to avoid putting unnecessary stress on the joints, which could lead to further leaks.

Utilising professional gas fitting repair services can significantly enhance the effectiveness of the reassembly process. Experienced technicians understand how to achieve the right balance of tightness while maintaining integrity in the fittings. Once the joint is reassembled, it's crucial to allow any sealant used to set according to the manufacturer's instructions, ensuring a robust and lasting seal for safety.

Techniques for Proper Reassembly

When reassembling a gas joint, it’s essential to ensure that all components are clean and free from debris. Start by inspecting the surfaces of the joint to confirm they are smooth and undamaged. Align the parts carefully, ensuring that they fit snugly together. When tightening, apply even pressure using an adjustable wrench or appropriate tool. It’s crucial to follow the manufacturer’s specifications regarding the torque to avoid damaging the joint while securing a proper fit.

After assembling the joint, double-check that the sealing materials have not been displaced. This step is vital to prevent future leaks. If you are unsure about the reassembly process or lack experience, consider consulting a professional for gas fitting repair services. Engaging experts helps ensure that everything is correctly fitted and reduces the risk of leakages, which can lead to hazardous situations.

Testing for Leaks Post Seal

To ensure that the seal on a gas joint is secure after applying a sealant, conducting a thorough leak test is essential. One effective method is to use a mixture of soapy water. Apply this solution generously around the sealed joint and observe for any bubbles forming. If bubbles appear, this indicates a leak, signalling the need for further attention. Taking safety into consideration, ensure good ventilation and avoid any open flames during the testing process.

If you identify a leak, it may be prudent to seek professional assistance. Gas fitting repair services provide expertise in assessing and rectifying issues that could compromise safety. Qualified professionals can offer solutions beyond just resealing, ensuring the integrity of the entire gas system. Regular maintenance and checks can help prevent leaks from developing in the first place, ultimately safeguarding both property and individuals.

Methods to Ensure a Secure Seal

To ensure a secure seal after applying sealant to a leaking gas joint, it is critical to allow adequate curing time as specified by the manufacturer. This period enables the sealant to form a durable bond, effectively preventing any gas escape. Additionally, tightening the joint to the correct torque specification is essential. Over-tightening can lead to damage, while under-tightening may not achieve the necessary seal.

Furthermore, employing a gas leak detector can provide peace of mind after reassembly. These detectors are designed to identify even minor leaks, enhancing safety in the area. For those uncertain about their ability to complete the task, professional gas fitting repair services can offer expertise. They can ensure that appropriate sealants and techniques are utilised, significantly reducing the risk of leaks in the future.

FAQS

What should I do first if I notice a gas leak?

If you suspect a gas leak, evacuate the area immediately and contact your gas supplier or emergency services. Do not attempt to seal the joint before ensuring your safety.

What types of sealants are suitable for gas joints?

Suitable sealants for gas joints include PTFE tape, anaerobic sealants, and specific gas-rated sealants. Always check that the sealant is approved for use with gas.

How do I apply sealant to a gas joint?

Clean the surfaces thoroughly, apply the sealant evenly to the male threads, and ensure that it does not clog the joint. Follow the manufacturer's instructions for the best results.

What techniques should I use for properly reassembling a gas joint?

When reassembling, align the joint accurately and hand-tighten it before using a wrench to secure it further. Avoid over-tightening, as this can damage the joint.

How can I test for leaks after sealing a gas joint?

You can test for leaks by using a soap solution; apply it to the sealed joint and look for bubbles forming. Alternatively, use a gas leak detector for a more precise assessment.