Table Of Contents

Safety Measures in Handling Fitting Line Gas

Handling fitting line gas requires strict adherence to safety measures to prevent accidents and ensure the well-being of personnel. Personnel should always use appropriate personal protective equipment (PPE), including gloves, goggles, and flame-resistant clothing. Training is essential; workers must be knowledgeable about the hazards associated with gas and the proper procedures for handling it. Regular safety drills can help reinforce this knowledge and prepare teams for emergency situations should they arise.

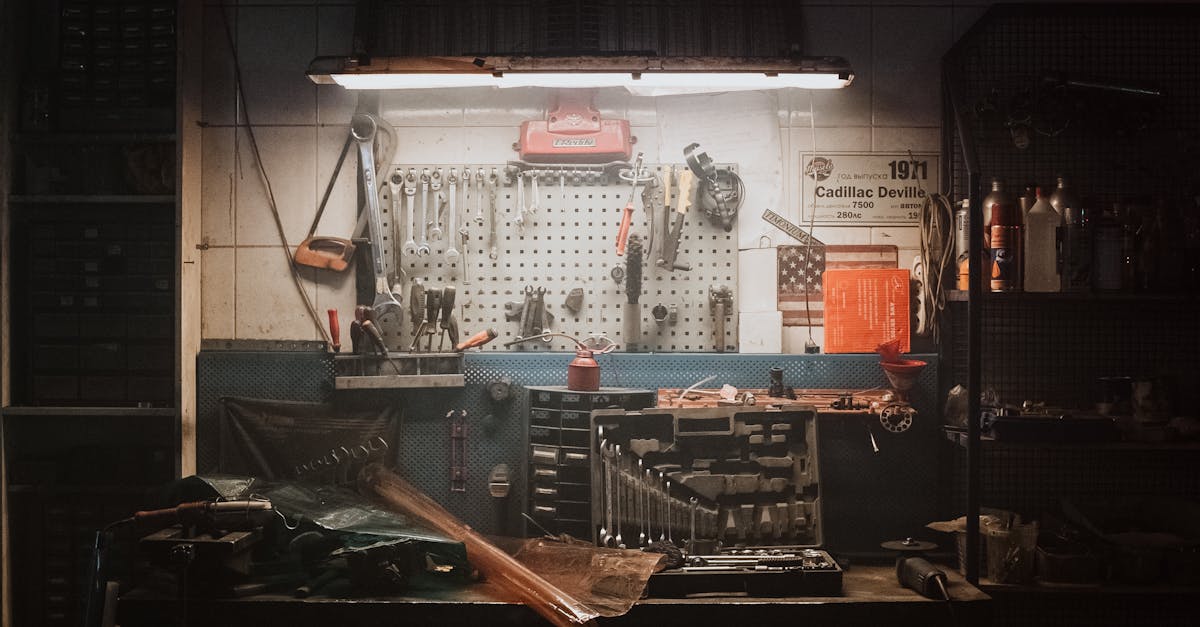

In addition to personal safety, facilities must implement rigorous maintenance protocols. This includes regular inspections of gas lines, connections, and valves to identify potential leaks or corrosion. Engaging professional gas fitting repair services ensures that any issues are addressed promptly and effectively. Keeping clear signage in areas where gas is present can also alert staff to the potential dangers, fostering a safer working environment.

Best Practices for Safety Compliance

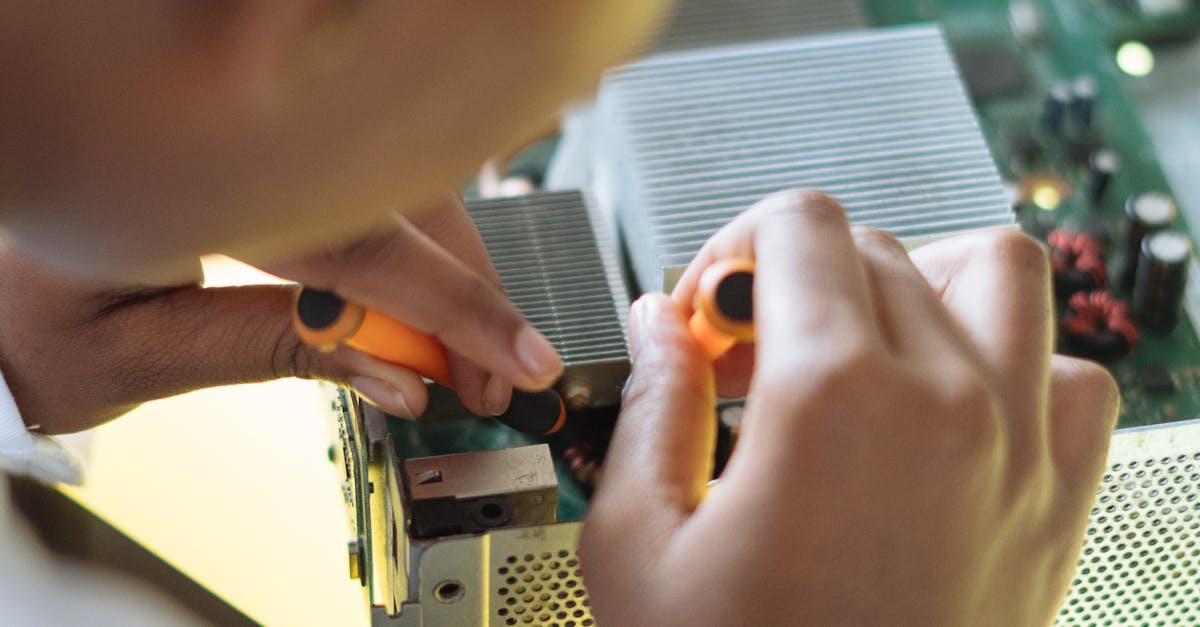

Ensuring safety compliance when working with fitting line gas requires a proactive approach. Utilising gas fitting repair services from certified professionals can significantly mitigate risks associated with improper handling or maintenance of gas lines. Regular training sessions for staff, focusing on the latest safety protocols and regulations, are essential. This not only enhances awareness but also reinforces a culture of safety within the workplace.

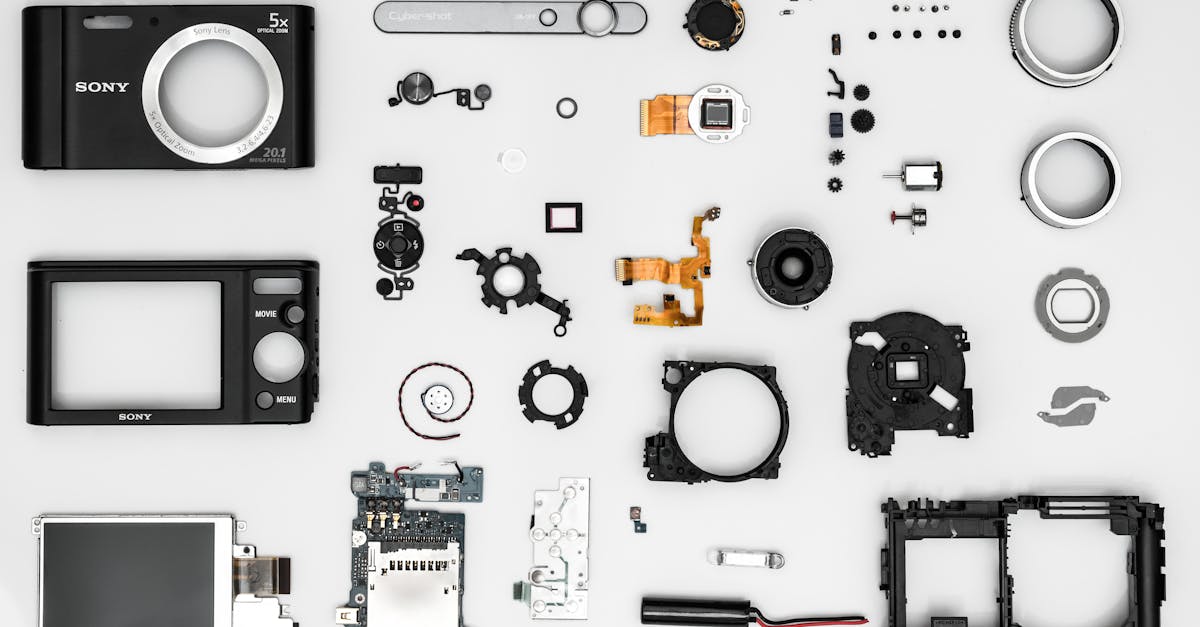

Implementing a rigorous inspection schedule for gas fittings and associated equipment is vital. Experienced technicians should conduct these checks to identify potential issues before they escalate. Maintaining comprehensive records of all inspections and repairs aids in compliance and fosters accountability. Additionally, having readily accessible safety data sheets can guide employees in emergency situations, ensuring they have the necessary information at hand to respond effectively.

Maintenance of Fitting Line Gas Infrastructure

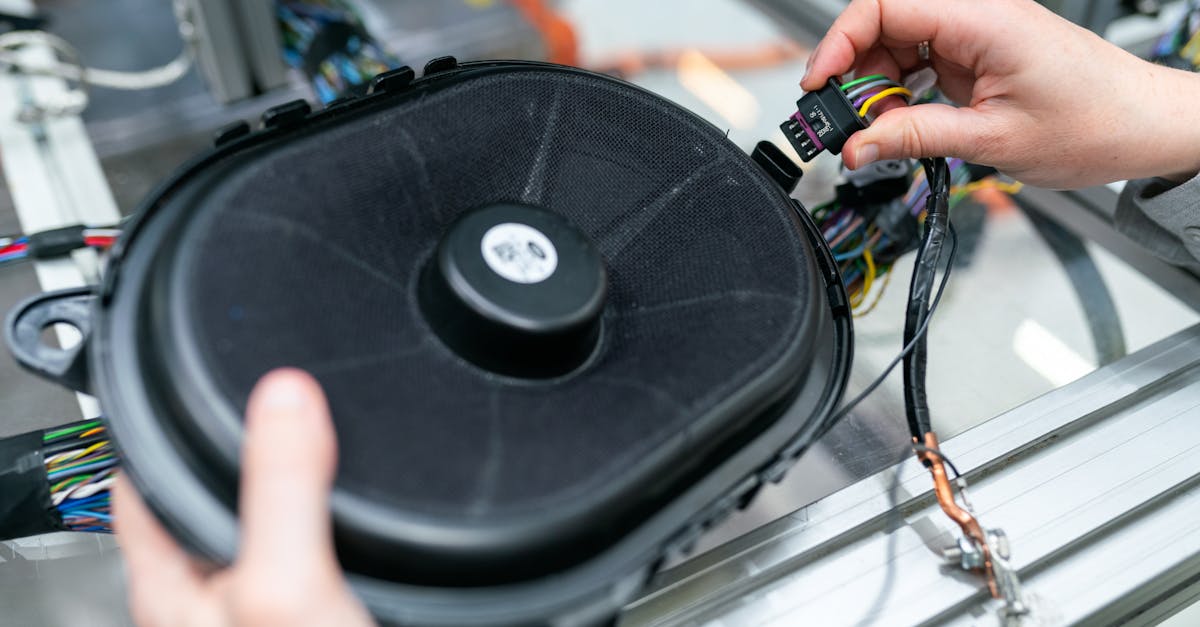

Regular maintenance of gas fitting infrastructure is essential to ensure optimal functionality and safety. This involves systematic inspections of pipelines, valves, and other components to identify any potential wear or leaks. Routine checks can prevent significant failures that may lead to hazardous situations. Implementing a maintenance schedule will not only prolong the life of the infrastructure but also foster a safer environment for both workers and the surrounding community.

In cases where issues are detected, prompt action is required, including the use of professional gas fitting repair services. Qualified technicians play a crucial role in addressing repairs and ensuring compliance with safety standards. Their expertise helps mitigate risks associated with gas leaks and improves overall system reliability. Investing in these services can save costs in the long term and enhance the effectiveness of the gas fitting infrastructure.

Regular Checks and Procedures

Regular checks of gas fitting systems are crucial to ensure safety and functionality. Technicians should conduct inspections to identify any potential leaks or wear in the infrastructure. This proactive approach helps in preventing hazardous situations that could arise from undetected faults. Furthermore, maintaining records of these inspections provides valuable insights into the system's performance over time, facilitating informed decisions regarding necessary repairs or upgrades.

Routine maintenance procedures should incorporate not only visual inspections but also pressure tests as required. Engaging professionals who offer gas fitting repair services can enhance the reliability of the system. These experts are equipped to address issues efficiently, ensuring compliance with safety regulations. Additionally, implementing a regular maintenance schedule not only mitigates risks but also prolongs the lifespan of gas fitting infrastructure.

Environmental Impact of Fitting Line Gas

Fitting line gas plays a significant role in various industries, yet its environmental implications cannot be overlooked. Emissions from gas systems can contribute to air pollution, affecting both local ecosystems and public health. With the growing concerns regarding climate change, there is increasing pressure to monitor and mitigate these impacts, ensuring sustainable practices are implemented throughout the gas supply chain.

Efforts to address these environmental challenges often include the use of gas fitting repair services. Regular maintenance and inspections can help identify leaks and inefficiencies, reducing harmful emissions into the atmosphere. Additionally, adopting advanced technologies in gas fitting can improve overall energy efficiency while minimising the ecological footprint of operations. Emphasising sustainability in gas management reflects a commitment to both regulatory compliance and environmental stewardship.

Sustainability Concerns and Solutions

The environmental impact of fitting line gas poses significant challenges that necessitate attention and action. Emissions from gas leaks can contribute to greenhouse gases, exacerbating climate change issues. Elevated methane emissions associated with natural gas production and distribution have raised concerns among environmentalists. Implementing rigorous monitoring and reporting protocols is essential to mitigate these risks.

Adopting innovative technologies can enhance the sustainability of gas fitting operations. Upgrading to more efficient systems and employing gas fitting repair services can significantly decrease leakage rates and minimise waste. Encouraging a shift towards renewable energy sources can also support a transition away from reliance on fossil fuels. Collaborative efforts between industry stakeholders and regulatory bodies are crucial to develop solutions that prioritise environmental health while maintaining energy efficiency.

FAQS

What is fitting line gas?

Fitting line gas refers to the natural gas or other gases that are delivered through a network of pipelines connected to various fittings and appliances within a facility or infrastructure.

What safety precautions should be taken when handling fitting line gas?

Safety measures include wearing appropriate personal protective equipment (PPE), ensuring proper ventilation in work areas, conducting regular training for staff, and adhering to established safety compliance guidelines.

How often should the infrastructure for fitting line gas be maintained?

Regular checks and maintenance should occur according to the manufacturer's recommendations and local regulations, typically on a routine basis, such as annually or bi-annually, to ensure safety and efficiency.

What are the environmental impacts of fitting line gas?

The environmental impacts can include greenhouse gas emissions and potential leaks, which contribute to air pollution and climate change. Sustainable practices and technologies can help mitigate these effects.

What best practices can be implemented for safety compliance with fitting line gas?

Best practices include conducting regular risk assessments, maintaining documentation of safety procedures, ensuring proper installation and maintenance of fittings and valves, and fostering a safety culture within the organisation.