Table Of Contents

Moisture Meters

Moisture meters serve as essential tools in identifying hidden leaks within buildings and other structures. These devices measure the moisture content in various materials, providing insights into potential water damage that may not be immediately visible. By inserting probes or using non-invasive methods, moisture meters can accurately pinpoint areas with excessive moisture levels. This data plays a crucial role in leak detection and repair, allowing property owners to take timely action to prevent further damage.

The effectiveness of moisture meters varies depending on the type used. Models range from simple handheld devices to advanced digital units, each designed for specific applications. By selecting the appropriate moisture meter, professionals can achieve accurate readings in different materials, including wood, concrete, and drywall. Regular monitoring using these instruments is key in maintaining the integrity of a structure, as they facilitate early detection of moisture issues that could lead to significant repairs if left unaddressed.

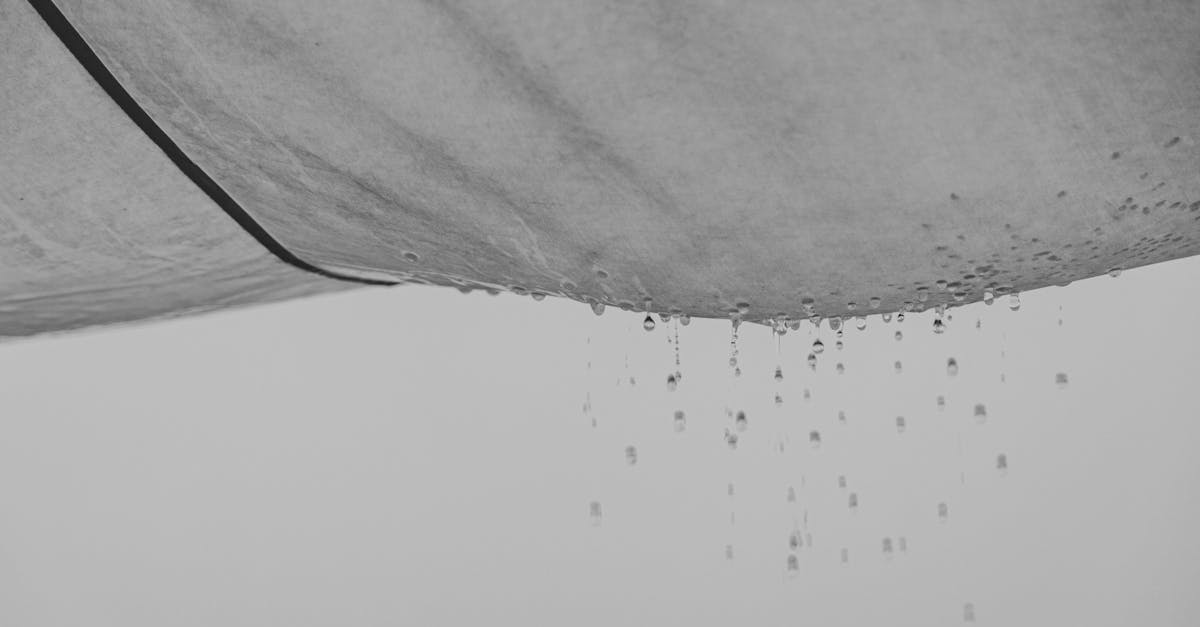

Measuring Humidity Levels

Measuring humidity levels is an essential process in identifying potential leaks within structures. High moisture readings can indicate hidden water intrusion, making it a crucial step for effective leak detection and repair. By using specialised devices, professionals can assess moisture content in walls, ceilings, and floors. This method not only helps to pinpoint existing issues but also informs preventative measures to safeguard against future leaks.

In addition to identifying current leaks, measuring humidity can uncover areas where mould growth may occur. Elevated humidity levels are often a precursor to such problems, highlighting the importance of regular monitoring. Implementing routine inspections with humidity meters can significantly enhance the accuracy of leak detection and repair efforts, ensuring a comprehensive approach to maintaining the integrity of a building.

Ultrasonic Leak Detection

Ultrasonic leak detection employs specialised equipment to identify high-frequency sounds emitted by escaping gases or liquids. This method is effective in locating leaks that may not be visible to the naked eye. By capturing these sounds, technicians can pinpoint the exact location of a leak, making the process more efficient. The technology is particularly useful in noisy environments, where traditional methods may struggle to provide accurate results.

The equipment used for ultrasonic detection typically includes handheld devices that amplify high-frequency sounds. Technicians listen for anomalies in the soundscape around pipes, valves, and fittings, indicating potential leaks. This approach allows for proactive leak detection and repair, minimising damage and energy loss. By using ultrasonic leak detection, businesses can maintain operational efficiency while adhering to safety and environmental standards.

Capturing HighFrequency Sounds

Ultrasonic leak detection utilises specialised equipment that can capture high-frequency sounds generated by leaks. These sounds are often inaudible to the human ear, making ultrasonic technology extremely effective for identifying the precise location of a leak. By employing sensitive microphones and advanced signal processing, technicians can isolate these frequencies, allowing them to distinguish between normal operational noise and the specific sounds associated with air or gas escaping from pressurised systems.

This method is particularly useful in various environments, including industrial settings and residential plumbing. As leaks can lead to significant damage and waste, timely leak detection and repair are crucial. By adopting ultrasonic technology, professionals can ensure comprehensive monitoring of systems, enhancing the overall maintenance strategy while preventing costly repairs down the line.

Video Inspection

Video inspection has emerged as a vital technique in leak detection and repair, particularly within plumbing systems and industrial settings. This method involves the use of small, high-resolution cameras attached to flexible rods, which can navigate through pipes and ducts. By broadcasting live video feed to technicians, these cameras allow for an in-depth examination of the interior surfaces, enabling operators to identify leaks, blockages, and other potential issues with great accuracy.

The ability to visually assess the condition of pipes without needing to excavate or dismantle infrastructure is a significant advantage. It not only saves time but also reduces costs associated with traditional leak detection methods. Video inspection can also enhance preventative maintenance strategies, as early detection of wear and tear can lead to timely repairs, thereby minimising further damage and extending the lifespan of the systems involved.

Exploring Pipes with Cameras

Video inspection utilises advanced camera technology to explore the interior of pipes and plumbing systems. This method provides a visual representation of potential leaks or damages, allowing technicians to assess the condition of the infrastructure without invasive measures. Cameras, often equipped with LED lights, navigate through pipes, capturing clear images that highlight issues such as corrosion, blockages, or fissures. The non-destructive nature of this technique means that it can identify problems early, facilitating effective leak detection and repair before they escalate.

The use of video inspection can significantly enhance the efficiency of maintenance practices. By pinpointing the exact location of a leak, technicians can formulate targeted repair strategies, minimising disruption to the surrounding area. This method is particularly advantageous in complex plumbing systems where traditional leak detection methods may fall short. Implementing video inspections contributes to a proactive approach in leak detection and repair, ultimately saving time and resources while ensuring the longevity of the plumbing infrastructure.

FAQS

What is a moisture meter and how does it work?

A moisture meter is a device used to measure the moisture content in various materials, such as wood or drywall. It works by using electrical resistance or capacitance to assess moisture levels, helping to identify potential leak issues.

How do you measure humidity levels in a space?

Humidity levels can be measured using a hygrometer, which is a device that indicates the amount of moisture in the air. Regular monitoring of humidity can help identify areas prone to condensation, potentially signalling a leak.

What is ultrasonic leak detection?

Ultrasonic leak detection is a method that uses high-frequency sound waves to identify leaks in pressurised systems. It captures the sound emitted by escaping gases or liquids, allowing for quick and accurate leak identification.

How does video inspection help in leak detection?

Video inspection involves using cameras to visually explore pipes and infrastructure for signs of leaks or deterioration. This method provides a real-time view of the internal conditions, allowing for better diagnosis and assessment of the problem.

Are there any specific industries that benefit from leak detection methods?

Yes, various industries, including plumbing, HVAC, oil and gas, and manufacturing, benefit from leak detection methods. Effective leak detection can prevent costly damage, enhance safety, and improve operational efficiency in these sectors.